I was in North Raleigh recently to visit a startup, Advanced Materials Manufacturing, which has developed strong, lightweight metallic materials based on years of its founder’s research, much of it at N.C. State. The company, founded in 2016, has drawn a lot of interest.

Also visiting at the open house were representatives from our two U.S. senators. There was John Hardin, the executive director of the NC Board of Science, Technology & Innovation. Dennis Lewis, the head of DEFTECH, the state’s Defense Technology Transition Office showed up. Retired Maj. Gen. Nick Justice was there, too. He used to run the Army’s Aberdeen Proving Ground. Paula Gentius, chief of staff in the chancellor’s office at N.C. State, was also there. Not your ordinary startup, I thought. 800x2400mm Super Lager Aluminum Foam

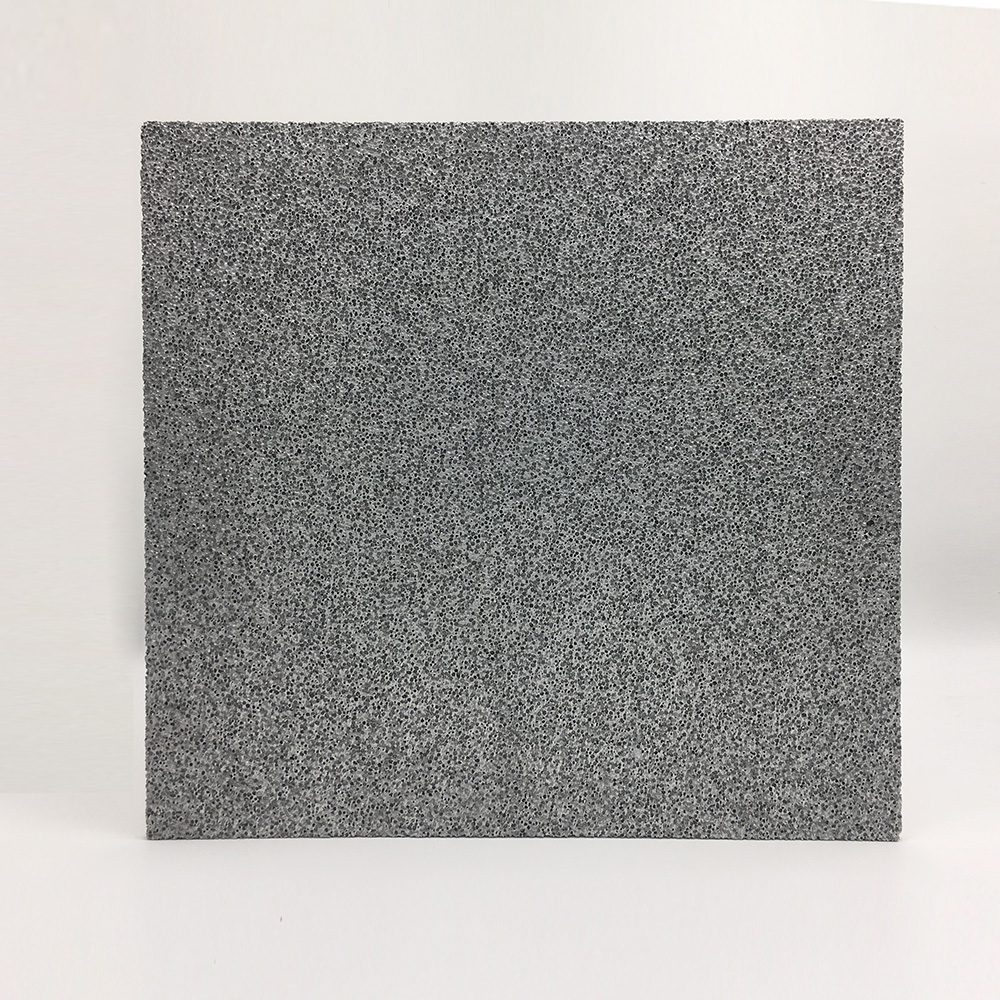

The company’s product is composite metal foam. It is made with impact-absorbing hollow metal spheres inside a matrix formed out of powdered or molten metal, which is then heated into a composite material that can be shaped for a wide range of uses. The tiny, hollow spheres – sort of metal bubble wrap – make it lighter than solid materials with comparable strength. CMF can protect against bullets and blasts. It does a good job resisting heat and fire and shielding against radiation.

There are lots of potential uses. Some of the most interesting are military applications. Speed is crucial in combat, but the tradeoff is less armor and protection. With composite metal foam, that tradeoff doesn’t have to happen.

“The strength, the weight, the cost-savings because you’re using so much less materials,” says Justice. “We’re talking about the potential of changing whole industries, not just ‘I got this one thing I can do.’ Can you imagine, every combat vehicle, I can cut the weight? You’re talking a game-changer.”

The company founder and CEO is Afsaneh Rabiei, a professor at N.C. State’s College of Engineering. She has an interesting story: undergraduate years during the Iranian Revolution; a doctorate in Tokyo; research at Harvard; and then on the N.C. State faculty since 2000. It is a story of persistence and resilience.

The story started one day in an Iranian industrial city when Rabiei went on a school trip to a factory. She saw red-hot steel rolling over platforms. In her words, she saw human power turning steel into “whatever shape we want.”

“This was my ‘wow’ moment to look into engineering,” she says.

In 1978, Rabiei entered Iran’s MIT, Sharif University of Technology, to study metallurgy; Each year, only 700 students were admitted from throughout the country. Already, the revolution was underway. In 1980, universities were closed. During this period, Rabiei kept studying, translating a classic textbook – Engineering Physical Metallurgy – from English into Farsi. The task required many trips to the library, and even the invention of new Farsi terms to express the complex concepts covered in the book’s hundreds of pages. A professor suggested getting it published. She did, as an undergraduate.

Her translation is still used in engineering schools in Iran. In fact, when Sharif reopened, it was used in one of her classes.

After graduation, she went to work as an engineer for companies that manufactured heavy equipment, copper products, and boilers and pressure vessels. In the early ‘90s, she got a full scholarship to the University of Tokyo, the top-ranked school in Japan. In 1997, she graduated with a doctorate in advanced materials. She then spent nearly three years doing postdoctoral research at Harvard.

In 2000, she came to N.C. State as a professor of mechanical and aerospace engineering. Her doctoral research had been in metal matrix composites – like combining carbon fibers with aluminum to make it harder. At Harvard, her research was in metal foam, introducing a gas or foaming agent into molten metal to make a porous and lighter-weight material.

At NC State, she decided to use her Tokyo and Harvard research experiences to create a new material – composite metal foam – with hollow spheres embedded in a solid metallic matrix. That would be strong and lightweight, the hollow spheres absorbing impacts by compressing.

It has exceeded her expectations. She told her team recently: “’God knows how many times I was surprised how well the CMF performs.’ I’m not saying this is a magic material that can do everything, but, for sure, it has a lot of benefits it can offer.”

Rabiei has spent the past 20 years building an impressive body of research and development in composite metal foam, with patents, peer-reviewed articles and tests to demonstrate the material’s ability. She has started a company, bought equipment, hired folks and been making CMF.

Rabiei has received federal funding from the National Science Foundation, Department of Energy, and the Department of Transportation. The DOE grant also resulted in a $75,000 award from the state’s One North Carolina Small Business Program run by Hardin’s outfit in N.C. Commerce.

Reading her patents, you get a glimpse of how much work has been involved in understanding, for example, how big the hollow spheres should be, what kinds of metal work best. Once the hollow spheres are surrounded in a mold by the matrix-forming metal powder or molten metal, there are questions of how much heat and time in the sintering process. And there are many other variables that fine-tune the product, depending on its intended use. There are many manufacturing questions that have been answered by the research she has conducted and led. And, so, CMF might be used in aviation and aerospace, in buildings in earthquake zones, or to develop lighter body armor.

In September, the company won a nearly $1.9 million award from a Department of Defense initiative, National Security Innovation Capital, which is part of the Defense Innovation Unit. DIU was set up to speed up the military’s adoption of commercial innovations that have defense applications, so-called “dual-use technologies.” It helped that Lewis, at DEFTECH, knew what Rabiei’s company was working on and let her know about the funding opportunity.

The challenge now for Rabiei is to raise more capital so she can expand and grow revenue.

She needs more space. Even as she plans to expand to an adjacent unit, that will just give her 7,000 square feet. She needs more like 50,000. She’s having to rely on someone else’s furnace right now, and needs her own. That could run up to $1.5 million. The company has four employees, and after filling some openings, she will have eight or nine. “We have customers lining up,” says Rabiei.

“As you can see, our shop is packed,” she says. “For the next five years, if we have all the equipment and all the resources, the number of employees would be more than 500.”

Rabiei’s company is what manufacturing needs to be in the U.S., with complex machines run by highly skilled technicians, and high-value products spawned by research coming out of our universities.

North Carolina used to be more of a blue-collar state, with a lot of textile, furniture and tobacco manufacturing jobs. As recently as 1990, more than 860,000 North Carolinians worked in manufacturing, around a third of the private sector workforce. A lot of those jobs vanished, hammered by the twin forces of foreign competition and automation.

Today, manufacturing employs about 12% of the private sector workforce, according to government statistics. A lot of effort is being put into growing back manufacturing employment, because the jobs pay well — if they are in technology-focused manufacturing. That’s a big focus of our community college system and engineering schools and economic development folks.

We pay a lot of money to out-of-state and international companies to bring advanced manufacturing jobs here – like car plants and battery factories. Jets and jet engine components. But we need to also make it possible for homegrown manufacturing startups to grow and stay here.

© Copyright 2023 Business North Carolina. All Rights Reserved

Metal Foam Properties Website by Web Publisher PRO