As a Products Finishing Top Shop, this company’s success with offering a variety of finishing services would not be possible without its employee dedication and the pride that’s been instilled in them to produce quality products for its long list of customers. #management #topshops #workforcedevelopment

Metal finishing, zinc plating, nickel chrome plating, electroless nickel plating, electrocoating, and powder coating: these finishing technologies are often individually offered by companies with the capabilities and skillset to handle each service. However, there are some established facilities in the industry that have grown to offer multiple finishing services successfully. Microfinish is one of these companies. With four facilities totaling 240,000 square feet in the St. Louis, Missouri, metropolitan area, it offers all the processes mentioned above with quality and efficiency to its 475-plus customers. China Molding Parts

The business has been a Products Finishing Top Shop for the past nine consecutive years, which Bill Stock, president, attributes to its employees who take pride in the company’s service to its customers.

“Our people are very attentive to the needs of our customers; they understand customer pressures and the need to get deliveries for their parts (quickly),” he says.

Microfinish, established in 1959, has gradually added processes and facilities through expansion and acquisition to meet the needs of its customers throughout the Midwest. Its customers include companies in the automotive, appliance, agriculture, lawn and garden, furniture and hardware industries. They are businesses that range from small machine shops that spend only a couple thousand dollars a year with the metal finisher, to large-volume suppliers to the automotive industry.

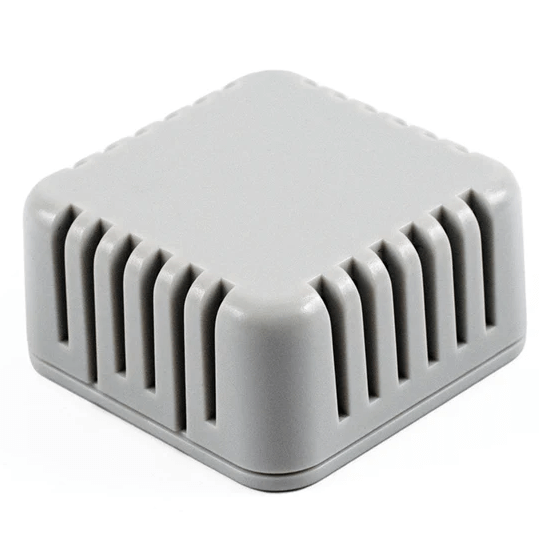

Microfinish, established in 1959, has gradually added processes and facilities in the St. Louis area through expansion and acquisition to meet the needs of its customers throughout the Midwest. Photo Credits: Microfinish

In its beginnings, the company’s one “mom and pop” shop tumbled stampings to remove burrs and smooth the surface finish of parts, improving the product’s “microfinish.” Then in the 1970s, company ownership decided to get “serious” about zinc plating.

“The company was doing electroless nickel, deburring, zinc plating, CAD plating, but with small tanks,” Stock explains. “So, they went out and bought a large return-style plating machine, and that’s how we really got into the plating market.”

By the mid-80s, the company expanded to add another plating machine as well as a wastewater system. In 1996, Microfinish decided to enter the powder coating business, adding capabilities for that technology. Then in 2005, it bought a mechanical finishing house, and in 2009 it acquired its largest facility where nickel chrome plating is done, as well as e-coating and large zinc-plated parts. In 2016, it acquired an electroless nickel line.

“We are four companies blended into one,” Stock explains.

In 1996, Microfinish decided to enter the powder coating business, adding capabilities for that technology. Currently, the company also specializes in metal finishing, zinc plating, nickel chrome plating, electroless nickel plating and electrocoating.

Although he continues to look for growth opportunities, Stock says there are no immediate plans for expansion. However, he is keeping an open mind to the possibilities.

Once at 90 employees, Microfinish has 72 currently. Stock says he would like to get that number closer to 100, but it is difficult to find people who commit to the job. However, he has found ways to focus on retention for his loyal workers, and as a result, the company has many long-time employees.

“To keep our good employees, we have bonus programs in place that seem to be fairly effective,” Stock says. “One thing we’ve tried to do to recruit people is instead of paying a new employee a finder’s fee for them coming on, we try to pay our employees for finding someone to bring in.” Stock has strategically used the money he was paying for temp services over a 90-day period and has given it to the employees who referred the new employees.

Although he desires to build his workforce, Stock believes in keeping the company at less than 100 people. He says it provides an atmosphere of a small company. “The most we have is 35 or so in one shop,” he explains. “I think it keeps it more on a personal level, and everyone knows each other better.”

This Microfinish employee is unracking parts that were nickel chrome plated. The company’s customers include those in the automotive, appliance, agriculture, lawn and garden, furniture and hardware industries.

When asked why he believes the industry is not seeing loyalty from candidates for employment, Stock says he thinks many companies have been “ghosting” employees for years, so now it is coming back to haunt employers. Employers are shocked when people ghost them (accept a job offer and then do not show up on the first day of work), but when a person interviews with a company and the company never gets back to them to tell them they filled the position, that is ghosting as well, he explains.

Being recognized by PF’s Top Shops program year after year has certainly boosted Microfinish’s employees’ confidence. “It makes them feel good about what they are doing,” Stock explains. “I think the benefits of our people knowing that we’re a Top Shop is even more significant than trying to sell it to our customers.” He adds that it is nice to have someone from the outside saying, “You’re doing pretty good.”

The detailed reports provided by the benchmarking survey give shops the opportunity to see their strengths as well as their deficiencies. According to

Pictured are tubes running on a zinc plating line at Microfinish.

Stock, the information is helpful because often management is too busy putting out fires, and trying to hire employees and find new customers to have time to reflect on how to improve and the aspects of the business that are done well.

As a professional who has been in the finishing industry for a long time, Stock has learned the importance of immersing himself in the industry via trade associations and other opportunities for networking with colleagues from outside of his company.

“I’m on the board of directors for the National Association for Surface Finishing (NASF),” he says. “I think it is very important for us to be involved in our industry because you help mold the future, and you get first-hand knowledge of what’s going on in the industry.”

Meeting and socializing with people who share the same struggles and can offer advice is invaluable. For instance, Stock says during the COVID-19 pandemic, there were many issues coming out quickly that the NASF funneled through its brain trust to work together.

Each year PF conducts its Top Shops Benchmarking Survey, offering shops a tool to better understand their overall performance in the industry. The program also recognizes shops that meet a set of criteria to qualify as Top Shops.

Twin Cities job shop, Avtec, was named a Top Shop for the third time in 2022, due in no small part to its commitment not only to the work it produces but to those who produce it — its employees.

This six-person shop rallies together to offer diverse finishing jobs that are growing to include custom show parts for automobiles and motorcycles.

China Nylon Cnc Machining Copyright © 2024 Privacy Policy [Log On]